京华提示:同等质量比价格,同等价格比服务,货真价实才是硬道理!!

本公司生产的产品有:建筑采光系列有:有机玻璃采光罩、玻璃钢采光罩、聚碳酸酯PC耐力板采光罩、阳光板采光棚、温室大棚、自行车棚,防爆天窗,抗爆天窗,泄爆天窗、泄压天窗,泄爆泄压通风天窗,泄爆门窗系列。玻璃钢系列有:玻璃钢冷却塔、玻璃钢水箱、玻璃钢通风柜、玻璃钢通风机、玻璃钢通风管道、玻璃钢防腐防水工程施工以及洁净厂房、玻璃钢浮雕工艺制品等多种系列产品的安装与施工。产品已安装使用在全国20多个省、市、自治区以及援外工程上。

There are various engineering methods for electric lighting and smoke exhaust skylights. They can be implemented on the original curtain wall side windows, or they can be made according to customer conditions, whether it is a concrete beam structure roof, a color steel roof, or a grid light steel structure roof. Construction, we can completely make it according to your actual needs. The control systems of electric lighting and smoke exhaust skylights are basically the same. They are connected to the fire protection system through the central control box to receive fire commands. When the fire signal is transmitted to the control box, the control box drives the motor of each skylight to open the skylight, thereby opening the skylight. Smoke is discharged to avoid personal injury. Electric lighting and smoke exhaust skylights have various forms in the production of lighting skylights. The lighting panels can be made into dome-shaped, orphan-shaped lighting cover skylights, or pyramid-shaped skylights. The material can be polycarbonate plate, organic glass plate, fiberglass plate, etc. In addition to the conventional one-sided top-opening structure, the structural form can also be made into: dome-shaped electric lighting and smoke exhaust skylights, triangular electric lighting and smoke exhaust skylights, straight-shaped electric lighting and smoke exhaust skylights, etc. Conventional practices | |

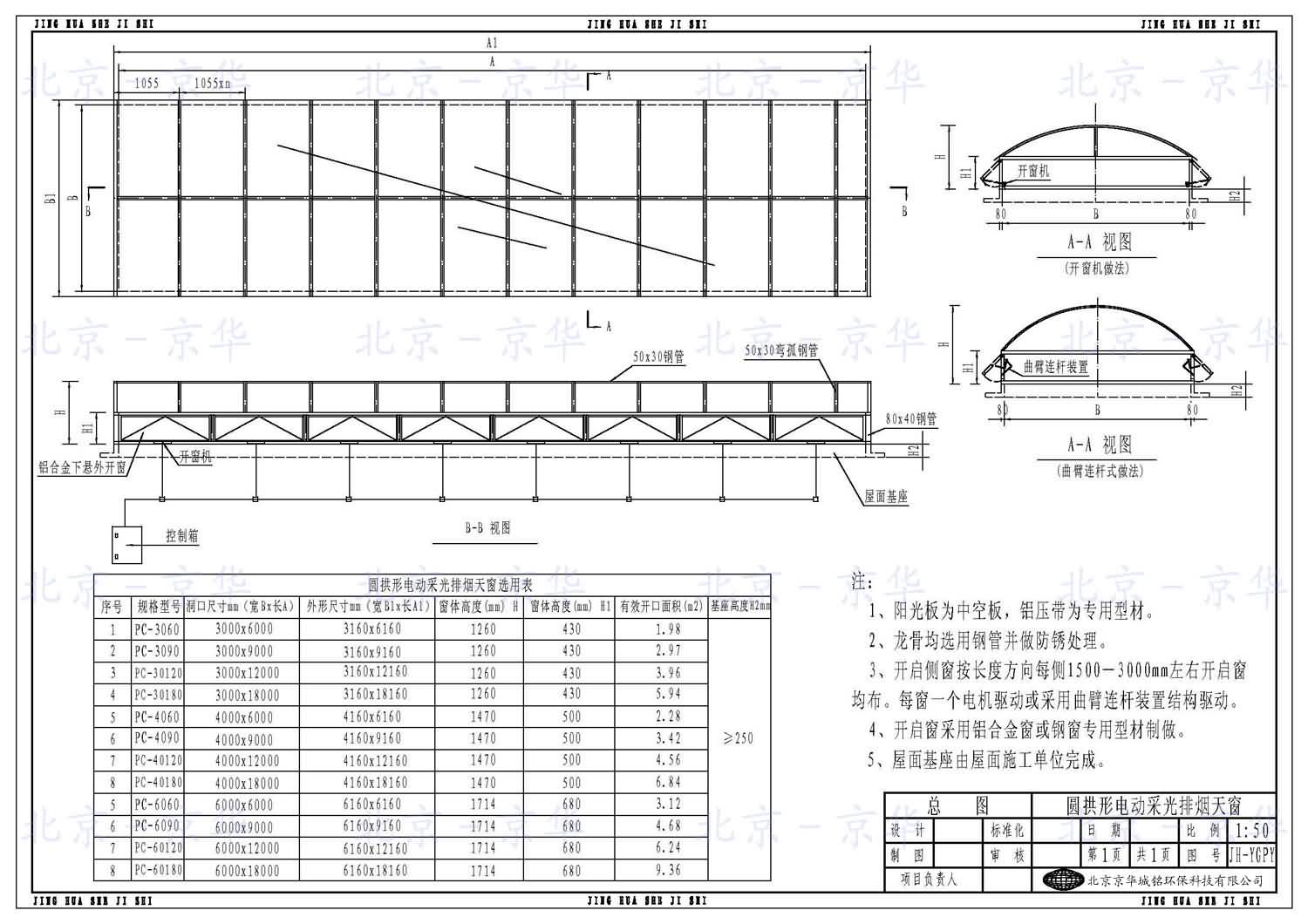

Arched electric lighting and smoke exhaust skylight: The opening size of the skylight and the height of the window sash can be made according to actual requirements. The control method for opening the window can be either a linkage method or a separate drive method. The structure of the electric lighting and smoke exhaust skylight is basically the same as that of the lighting shed. The dimensions in the picture are for reference only and should be corrected during actual production. >Refer to the picture on the right for how to do it |  |

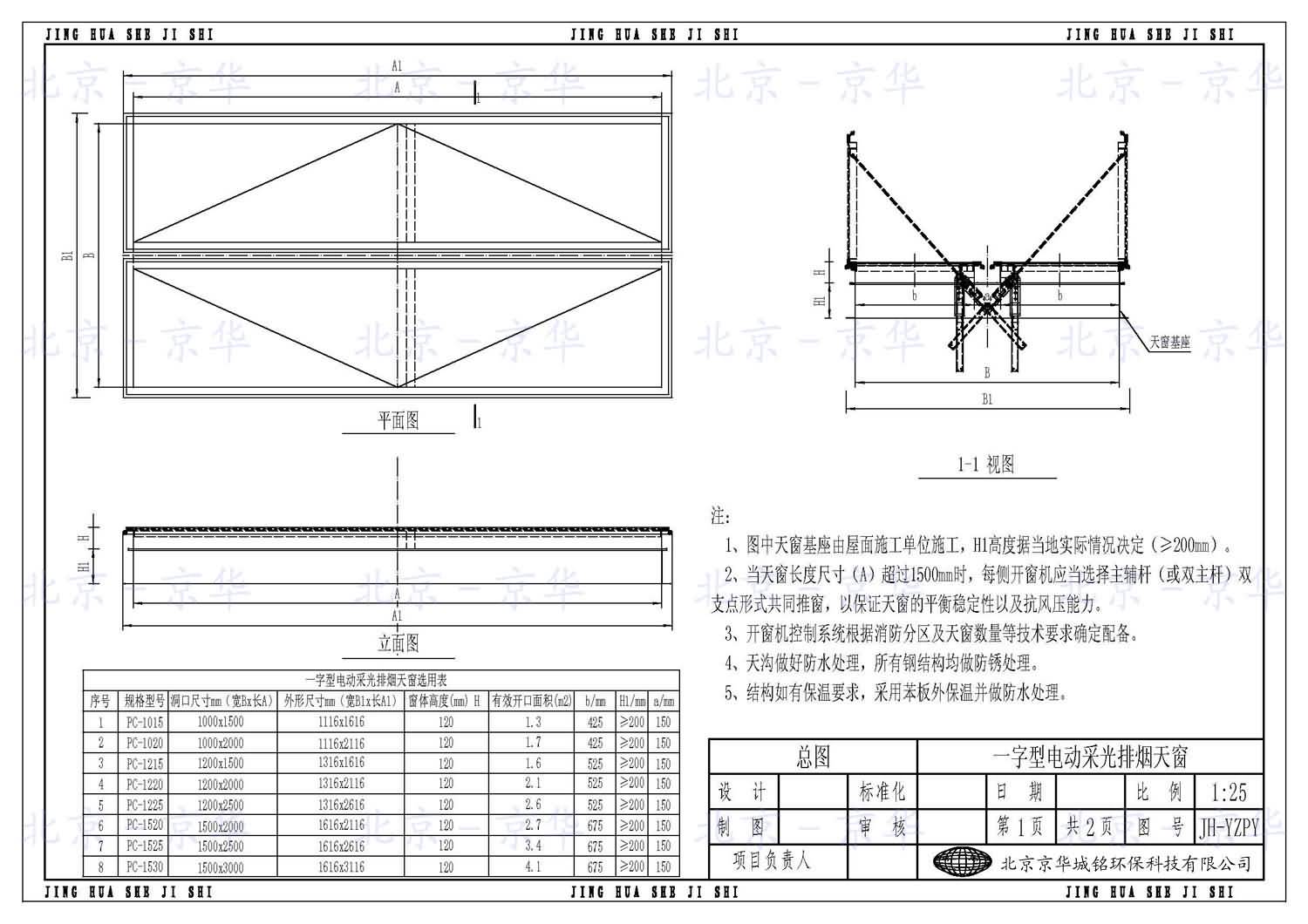

Straight-shaped electric lighting and smoke exhaust skylight: The structure of the straight-shaped skylight is the same as that of other electric windows, except that it is divided into two parts with a drainage ditch in the middle. When the skylight is opened, it becomes a flat state. When the length of the skylight exceeds 1500mm, it is opened in the form of double pivots of the main and auxiliary rods. A chain-type window opener can also be used to push the window. The skylight opening angle is 0-90 degrees. The dimensions in the picture are for reference only and may be corrected during actual production. Various forms of electric lighting and smoke exhaust skylights can be flexibly designed and manufactured according to customer requirements. >Refer to the picture on the right for how to do it |  |

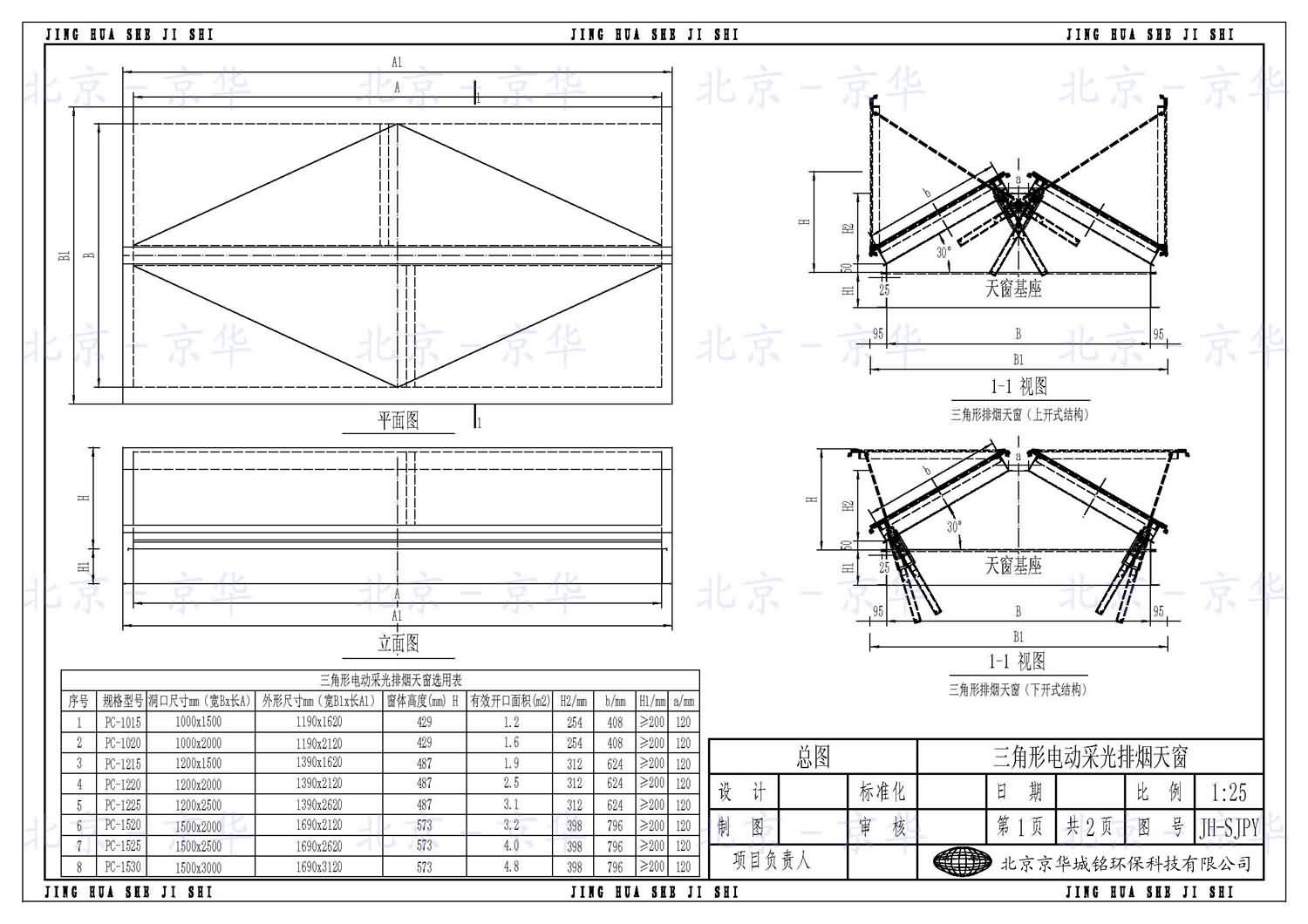

Triangular electric lighting and smoke exhaust skylight: The structure of the triangular skylight is similar to that of the straight skylight. When the skylight is opened, it becomes tilted. When the length of the skylight exceeds 1500mm, it is opened in the form of double pivots of the main and auxiliary rods, or a chain-type window opener can be used to push the window. The skylight can be opened in two ways as shown in the figure. The skylight opening angle is 0-60 degrees. The dimensions in the picture are for reference only and may be corrected during actual production. >Refer to the picture on the right for how to do it |  |

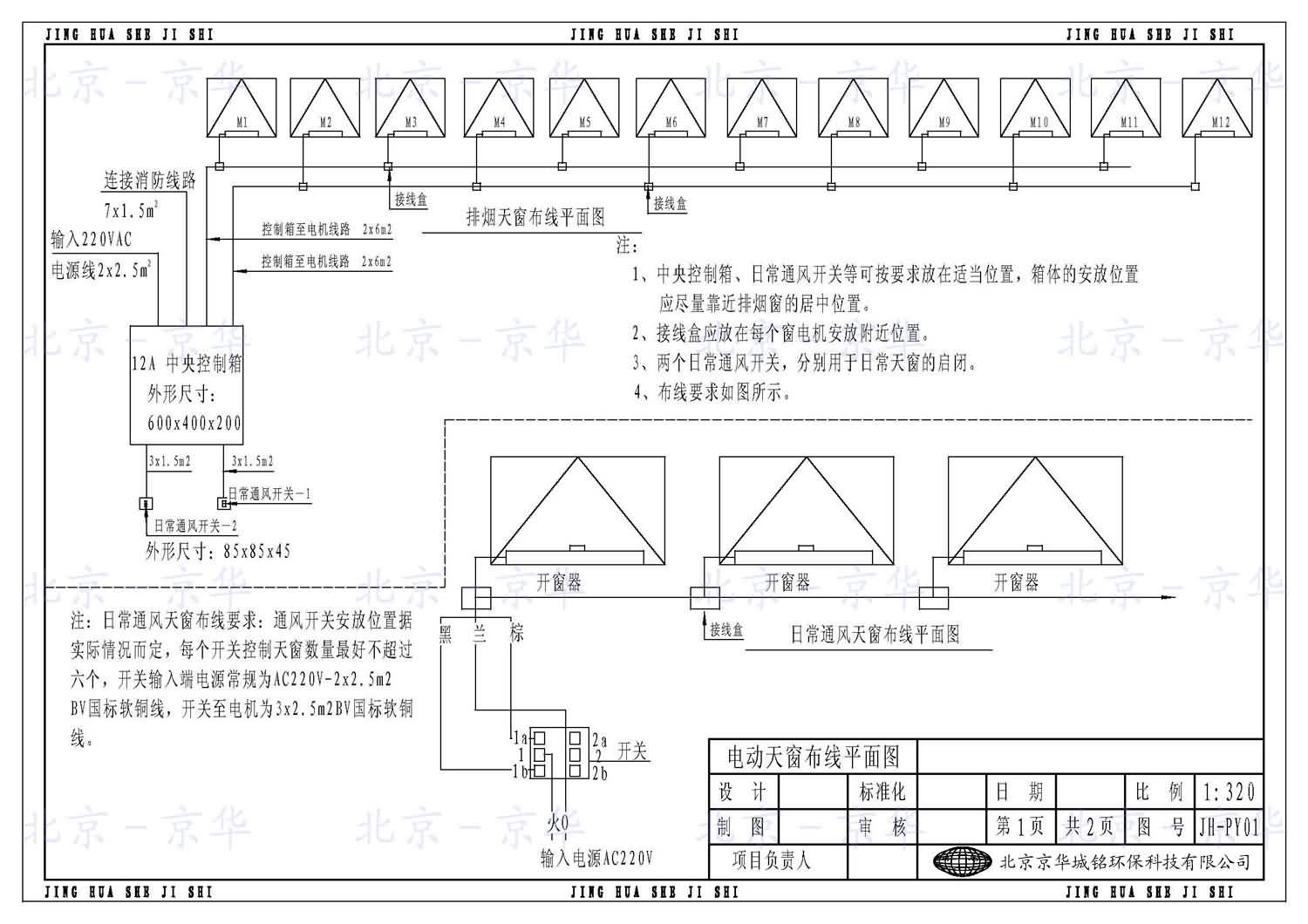

Conventional wiring scheme for smoke exhaust skylight: Smoke exhaust window: ⑴The opening and closing of each smoke exhaust window is completed by the central control box. Each central control box can output two rows of control lines (4 wires). Each row of control lines can be set with a daily ventilation switch to complete the operation when there is no fire command. Daily manual control of opening and closing of skylights. The control box can be controlled in conjunction with the fire protection system. When there is a fire protection command, other commands will obey the fire protection command unconditionally. The control box's backup power supply can ensure that the skylight is opened and closed twice within 72 hours after the power is cut off. If required, the control box can also be connected to the smoke sensor, wind and rain sensor, emergency button and other controller equipment. ⑵The number of central control boxes: set according to the project overview. The setting of the control box is comprehensively considered based on the distribution of smoke exhaust windows on the roof and the fire protection zone. The box should be placed as close to the center of the smoke exhaust window as possible based on the number and position of the control skylights. When placing the control box, do not place it together with other electronic control equipment to avoid magnetic field interference and cause disorder of the control system. Wiring requirements for smoke exhaust windows: (BV soft copper wire) ① Conventional wire diameter requirements: AC220V at the power input end of the control box: 2x2.5m2, fire access: 3x1.5 m2, fire feedback: 4x1.5 m2, daily ventilation switch: 3x1.5 m2, smoke detector: 3x1.5 m2, wind and rain sensor: 4x1.5m2, emergency button: 5x1.5 m2, control box to motor: 2x4-6m2. ② Wiring should be laid in steel pipes, and a junction box should be provided at the skylight terminals. And the distance from the terminal block should be less than 100m. ③ During wiring, wires of the same color are not allowed in the same steel pipe. ④ When wiring, the wires from the control box to the final skylight are prohibited from being cut in the middle. ⑤The input signal provided by the fire protection system should be a passive switch signal. Daily ventilation switch wiring requirements: (BV soft copper wire) input power AC220V: 2x2.5m2, switch to motor: 3x2.5m2. | |

Smoke exhaust window wiring plan >Refer to the picture on the right for how to do it |  |

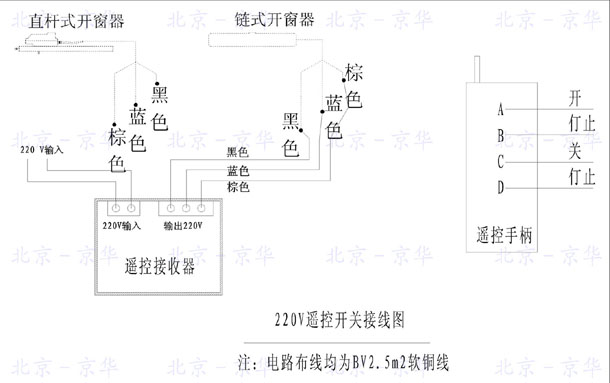

Remote control switch wiring scheme >Refer to the picture on the right for how to do it |  |

冀公网安备13112202000235号

冀公网安备13112202000235号